Multiple cavity tools for rubber mouldings

Rubbertech 2000 use various numbers of cavities in our rubber mould tooling. The economics of numbers of cavities for rubber moulding depends on tooling costs, on volumes of items required and on their unit costs.

Single or Multiple Cavity Tools for Rubber Moulding?

We ask for various details to generate quotations, one of these details is the quantities or volumes of parts required for production.

Your volume requirement and the volume over the lifetime of the product has an influence on how many cavities we recommend for your mould tool and how easily you will be able to justify your investment in the tooling.

A single cavity tool produces one part per cycle. For example, a cycle time of 12 minutes produces a maximum of 5 cycles per hour. This includes the time it takes to remove the moulded part from the mould tool and to load new rubber for the next cycle. So, in this scenario, we might produce 5 parts per hour.

Cycle Time

Well as mentioned there is the unloading and reloading of the tool, but also when the press closes, the rubber inside the mould tool is subjected to high temperatures and pressures, it flows through the mould and is then held until vulcanisation occurs. Curing times depend on the material and dimensions of the moulding.

The press is dedicated to this one mould tool so the whole costs of the press apply, while the press operator will be working perhaps 3 machines at different stages of their cycles so only a proportion of their cost is applied.

Single cavity tools cost less than multi-cavity tools, so capital expenditure is lower. But running at 5 cycles per hour means unit prices of parts produced from a single cavity tool will be quite high!

If you know the planned lifetime of your product, you can amortise the tooling cost over the lifetime of the item:

Tooling cost + (lifetime volume x unit cost) = total cost

When considering multi-cavity tools, a few things happen:

Firstly the tool will produce more parts per cycle.

The cost per unit will fall.

The capital cost of the tool will be higher because there is more metal to cut to produce the multiple cavities.

Finally, it may take the press operator a little more time to unload and reload the mould tool, depending on the tool design.

When we are talking about multiple cavities it is worth thinking about the sorts of multiples we are talking about.

A relatively low volume, medium sized part, might have 8 cavities giving perhaps 40 parts an hour. While a small, but high volume part (perhaps a grommet) might have 225 cavities, producing over 1,000 parts per hour.

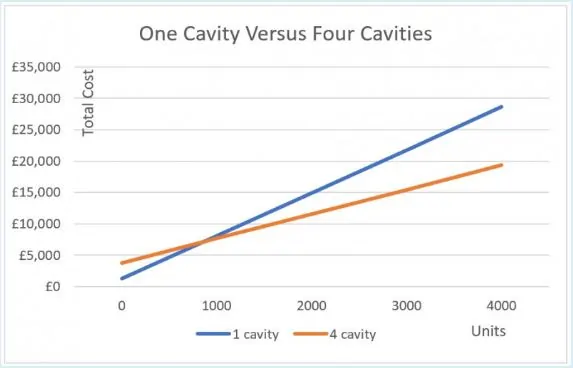

The simplest way to compare one to many cavities is to compare total costs.

1 Single Mould Tooling cost + (lifetime volume x unit cost1) = total cost1

2 Multiple Cavity Tooling cost + (lifetime volume x unit cost2) = total cost2

Say an item had a tooling cost of £1,300 for a single cavity tool and £3,800 for a 4 cavity tool with Unit costs of £6.83 per unit from the single cavity and £3.89 per unit for the 4 cavity option.

The 4 cavity option is more expensive initially because of the higher tooling cost but before 1,000 units have been produced, the total cost of the 4 cavity option is less than the single cavity. After more than 1,000 pieces, the gap keeps on increasing.

If you only want 500 mouldings you would choose single impression tooling, but if more than 1,000 then 4 cavity makes more sense.

Note: when comparing quotes from different moulders it is a good idea to know how many cavities they are quoting for as this can sometimes explain why the tooling from one potential supplier is more, or less, expensive than another.

Rubber moulders are usually going to recommend multiple cavity tooling because it is more economical, and it means moulding presses spend less time tied up on one job.

See also:

Keeping the mould tool hot

If you would like to discuss a moulding project, please get in touch, we will look forward to discussing your needs.