Rapid Prototyping & 3D Printing Experts

Prototyping & 3D Printing

Helping our customers at the earliest stages of new projects offers substantial advantages, especially in rapid prototyping services. Early engagement allows us to evaluate designs or collaborate to develop initial prototypes, ensuring parts are cost-effective while meeting the project’s objectives. This streamlined approach reduces time at each design stage, accelerates the product development process, and minimizes the need for costly design modifications later. Our comprehensive services include rapid prototyping, CNC machining, and rapid tooling, enabling us to create prototypes quickly in a cost-effective manner. These solutions support seamless transitions to low-volume manufacturing or full-scale production, helping clients achieve their goals efficiently.

To enhance project outcomes, we also provide functional prototypes and physical models, backed by detailed design and manufacturing analysis. Our expertise spans common rapid prototyping processes like injection moulding, ensuring the production of identical parts with consistent quality. We accommodate frequent design alterations without compromising timelines or standards, making our services ideal for projects requiring flexibility and precision. By focusing on initial parts and utilizing advanced manufacturing capabilities, we reduce risks, accelerate time to market, and support sustainable growth. Our experienced engineers ensure the selection of optimal technologies and materials, empowering clients to develop innovative products in an efficient, cost-effective manner.

We have several options available to us for creating functional models for testing.

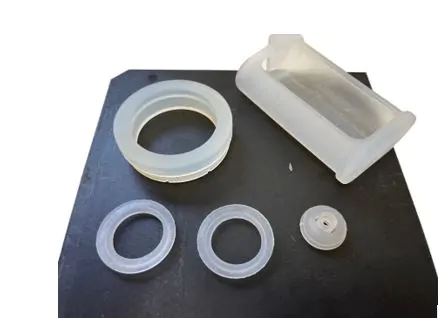

- Liquid silicone prototypes – Manufactured using high-quality liquid silicone, moulded in 3D printed tooling. This method is low-cost, quick and representative of production materials so perfect for testing sealing solutions as well as many more designs. Available in 5-7 days.

- Alloy Tooling (Rubber Mouldings) – Our specialist toolmakers can produce fast turnaround single impression tooling that can be used for prototypes and where required initial production. Available in 3-4 weeks

- Far East Tooling (Rubber Mouldings) – Although not as fast our partners in the Far East can produce single impression tooling for production quality samples at very low cost, once approved these tools would be suitable for production although larger tooling may be more cost-effective long term. Available in 5-6 weeks

- VAC Casting (Rubber Mouldings) – We work closely with UK partners who can supply RTV silicone prototypes or PU prototypes, these can be available in 7-10 days.

- 3D printing – We have in-house 3D printing capabilities that can print in carbon fibre-filled nylon (Markforged Onyx) offering high strength, high-quality functional parts with print layers as fine as 0.050mm. Available in 2-3 days. Our prototypes meet client specifications, ensuring quality and reliability. Creating one prototype allows for revisions and multiple iterations within a short timeframe. Our services also assist people with specific needs, providing user-friendly designs.

The rapid prototyping process is significant in product development, offering efficiency and flexibility. Various rapid prototyping processes, including 3D printing, CNC machining, and injection moulding, are used to quickly produce and iterate prototypes. We can print parts in varying sizes, maintaining precision and complex geometries depending on the scale and requirements of each stage. Our services are trusted by engineers and purchasing leaders for reliability and reputation. The effective functionality of our prototypes assists long-term performance and innovation.

For more information about our Prototyping and 3D printing services please contact our engineering sales team.